The development of mastering techniques for the Compact Disc has been greatly assisted by Philips' knowledge and experience with the LaserVision system. As with LaserVision mastering equipment, Philips can also supply and install mastering processing equipment for Compact Discs. But it is more than just equipment.

With Philips, it is a total service, which includes:

- Consultancy regarding clean room specifications and layout, together with purchasing requirements for equipment and materials

- Delivery of specific Philips mastering equipment

- Customer training in mastering techniques

- Installation and commissioning of mastering equipment

- Warranty, maintenance and repairs.

The complexity of the new concept, technologies and equipment, together with the allied costs involved in the production of Compact Discs, naturally precludes the installation of mastering equipment in every recording studio. For these reasons, initially, customized mastering and replication operations will be carried out in specifically designed replication facilities, thus providing an economic solution to customer requirements. Philips can also provide full services for customized mastering.

Optical Disc Mastering

Compact Disc Digital Audio - or CD - represents a new concept in sound reproduction techniques. The advance from the old "78" to today's LP pales by comparison. The CD system is based upon a digital recording technique with a laser-beam optical pick-up.

The true meaning of CD's contribution to sound reproduction can be seen in its performance figures. Dynamic range, signal-to-noise ratio and channel separation, all aproach infinity at over 90 dB. Between 20 Hz and 20.000 Hz, frequency response is completely flat. Harmonic distortion is less than 0,05%, and rumble, wow-and-flutter and microphony are eliminated.

The Compact Disc is single-sided - only 120 mm in diameter and 1,2 mm thick - yet it gives the same playing time as both sides of a conventional LP. And as the digital recording is sealed within the disc, its performance is unaffected by dust, scratches, and fingermarks. The small size of the Compact Disc also enables the size of the player to be reduced to around that of a compact cassette recorder. In addition, laser beam scanning eliminates problems of wear on either the disc or pick-up.

Programme material

To make the most of the advantages of the Compact Disc, digital (PCM) encoded programme material should be used. For multi-channel digital recording, the various inputs are mixed to provide a two-channel PCM-master (stereo) tape. This is then completed with the addition of the necessary control information (subware). Existing analogue recordings can also be used in the production of a Compact Disc, by first transferring them to a two-channel PCM-master tape. Whilst the use of analogue material will not enable the exceptional performance characteristics of a digital original, it still gives a markedly better result than that found on normal LP records.

Compact Disc Mastering

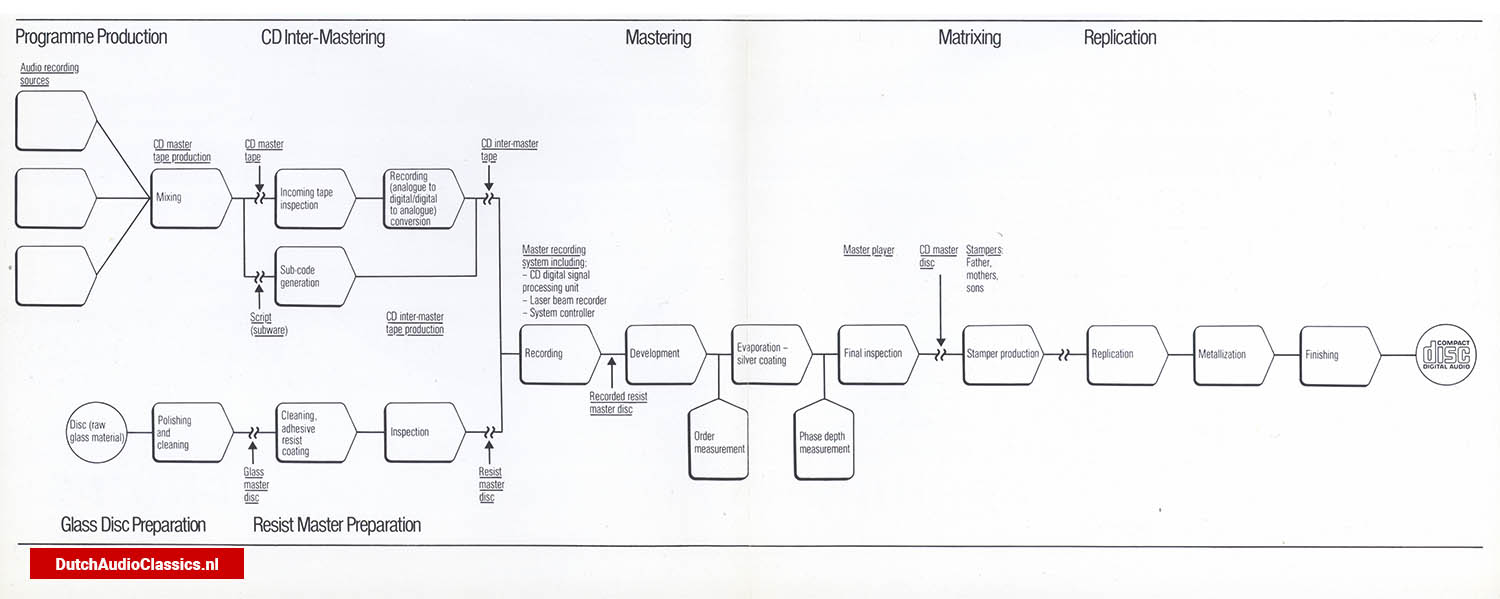

The mastering process for LP records requires a simple process of machine cutting a lacquer disc. Compact Discs on the other hand, require a complex set-up of differing processes, as can be seen in the flow diagram. There is considerable similarity between Compact Disc mastering and that of LaserVision Discs. The PCM signals from the master tape are processed and then transferred to the first disc-shaped carrier - the CD master.

Mastering takes place in a temperature and humidity controlled clean room environment. Apart from standard processing and measuring equipment, it also requires specific apparatus for substrate preparation, laser beam recording, substrate development, and final optical and electrical inspection. From this master, galvanic copies are made (similar to normal LP production), and they are used as stampers in the subsequent replication process.